TAMPING HEAD ATTACHMENT

S7 THA 8 4.0

Intelligent Tamping - The Revolution in Track Maintainance

Full-Hydraulic Drive

System7 has revolutionised tamping with excavators by integrating its full hydraulic tamping drive technology from the S7 tamping machine into an excavator tamping attachment.

Intelligent Tamping

The squeezing cylinders of the tamping banks are equipped with integrated position and pressure sensors. This enables a constant measurement of the ballast hardness. The amplitude and frequency are variable and controlled automatically. There is only vibration during insertion and compacting. Whilst tamping, the frequency of 35 Hz at the tamping drive is kept constant.

Automated Tamping Circles

An automated tamping cycle can be selected after pre-selecting the desired squeezing time, penetration depth and number of immersions per tamping cycle. After correct positioning of the tamping unit pressing the start button on the remote control starts the automatic tamping cycle. The penetration process, tamping and raising to rest position are then carried out fully automatically.

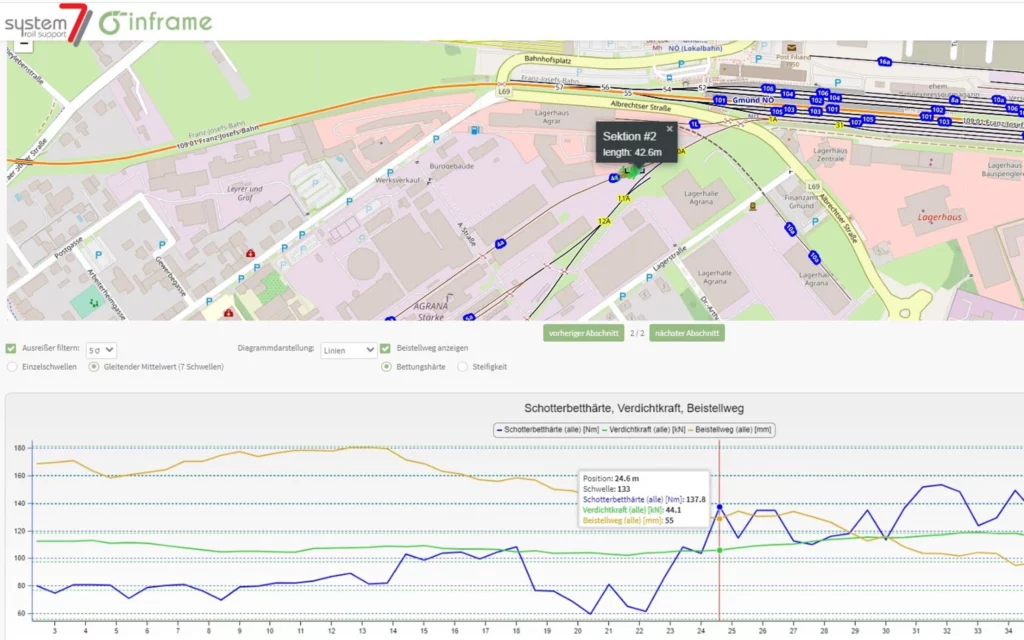

BALLAST BED ANALYSIS WITH SYSTEM7 INFRASTRUCTURE MANAGEMENT WEB PLATFORM "INFRAME"

Each squeezing cylinder collects data of achieved ballast compaction and squeezing path. Thereof a quality figure for the ballast bed hardness is derived. Tamping data is uploaded to “INFRAME” were the tamping job is visible on a map with related GPS coordinates and an image of each sleeper surrounding.

Huge Reduction At Wear

Rotating drive parts become redundant and the full hydraulic drive only vibrates during penetration and compaction of the ballast – the rest of the time it stands still. This results in a reduction of maintenance costs compared to conventional tamping banks.

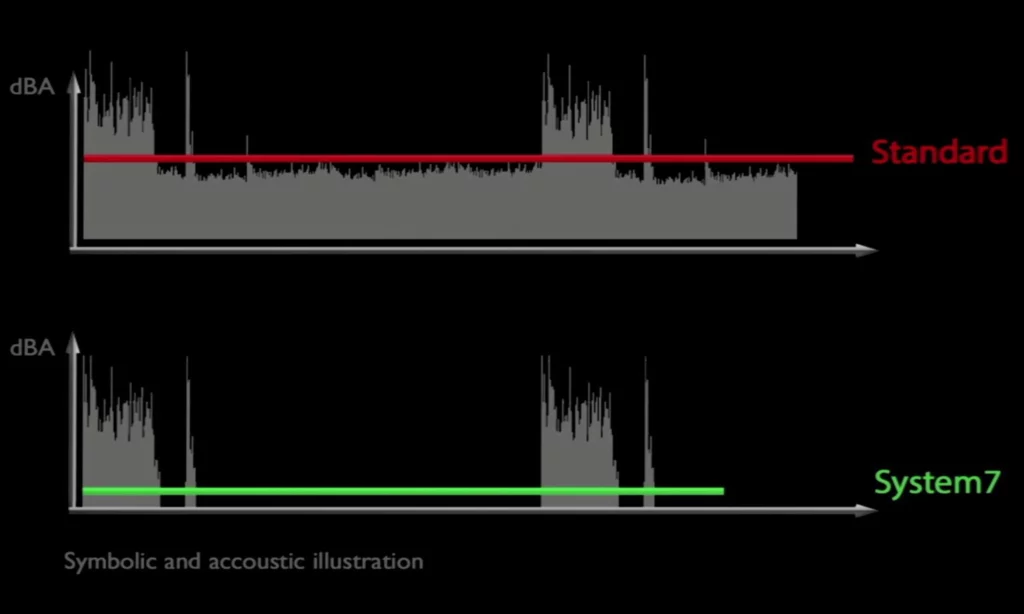

REMARKABLE REDUCTION OF NOISE AND DUST

The noise is significantly reduced by stand-still periods and emission of respirable dust more than 50% less in comparison with conventional tamping banks. This minimizes the burden of the operator and its surroundings.

FULL SWITCH COMPITABILITY

The opening width of the tamping banks is variable and is also suitable to tamp double sleepers. Beside simultaneous operation each tamping bank can be independently controlled and hydraulically slides out for working in switches.

Quick GAUGE ADJUSTMENT

As standard the wheels can be easily adjusted onto the required gauges of 1.000 mm, 1.435 mm or 1.600 mm. On customers request we can also offer other wheel positions for gauges between 750mm and 1.668mm.

IDEAL FOR SPOT REPAIR

Developed to close the gap between large and small maintenance works. For spot tamping the tamping head attached is ideal and prevents the costs of a dedicated tamping machine. The system7 mounted tamping unit delivers the technical advantages of fully hydraulic tamping for nearly all excavator models.

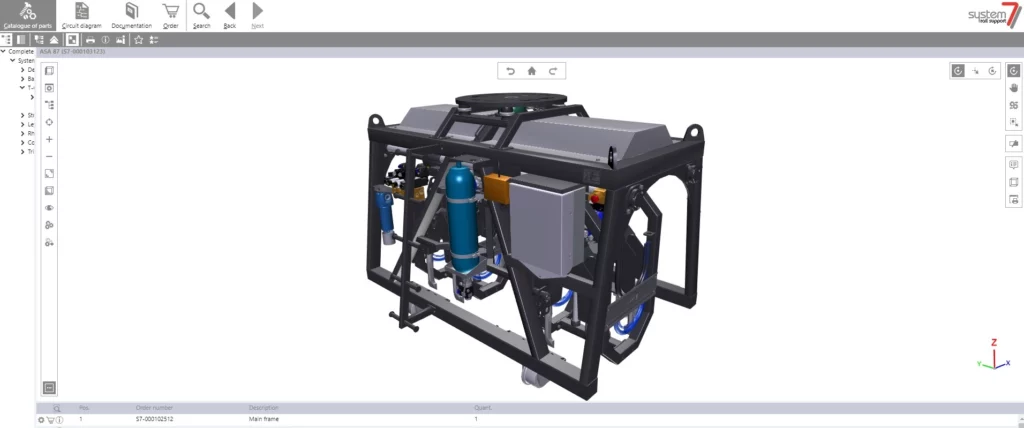

REMOTE DIAGNOSTICS AND SERVICE

Like the system7 universal tamper also the tamping head attachment offers remote diagnostics and service. Spare parts can get ordered online via the 3D spare parts catalogue.